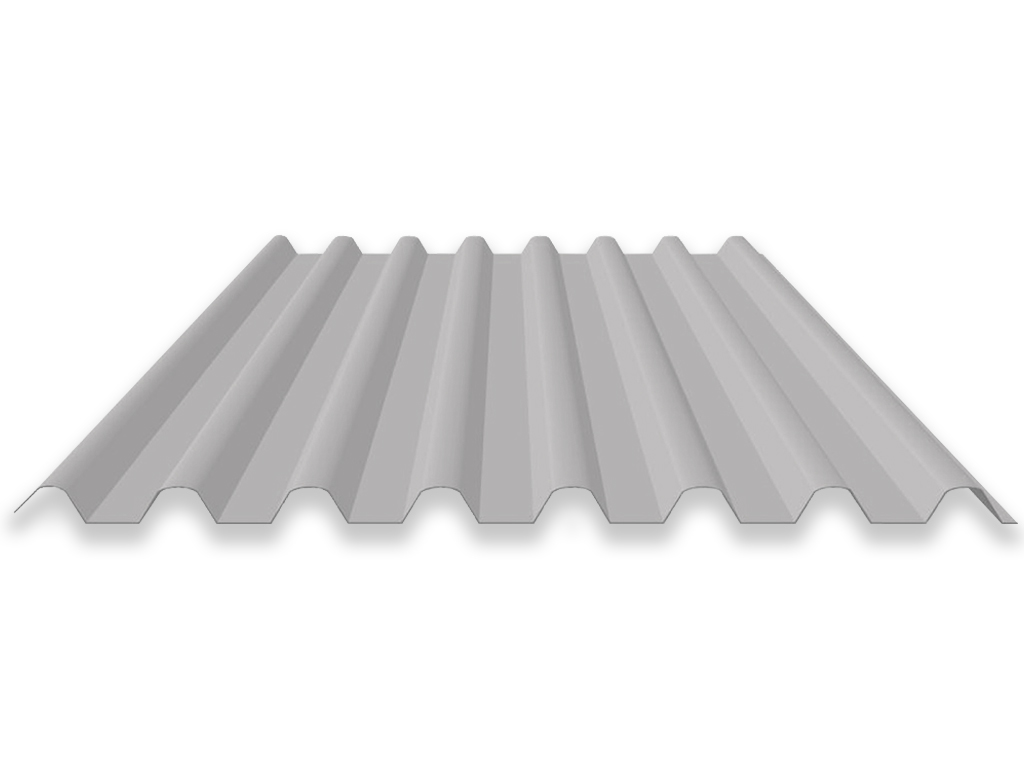

Stramit Longspan® is a good looking, long spanning high strength roof and wall sheet

Related products

-

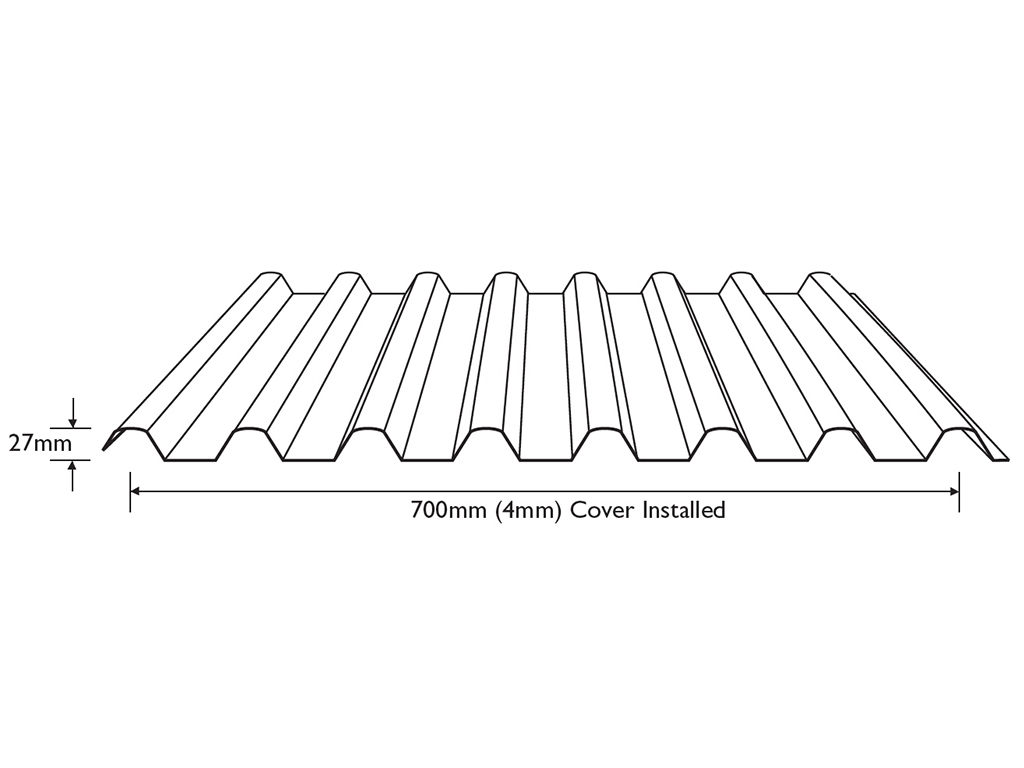

5 Rib (Trimdek equivalent) 0.48BMT Zincalume

$16.01 Exc. GST m -

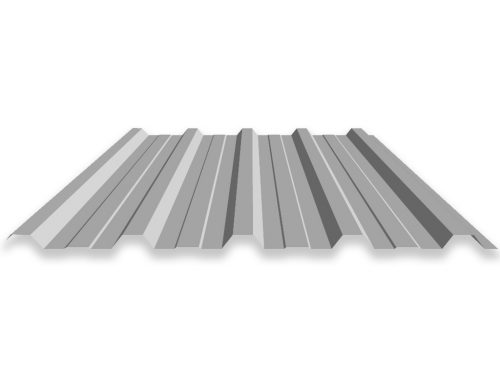

Capacity Plus 0.42BMT Colorbond

$30.11 / m Exc. GST -

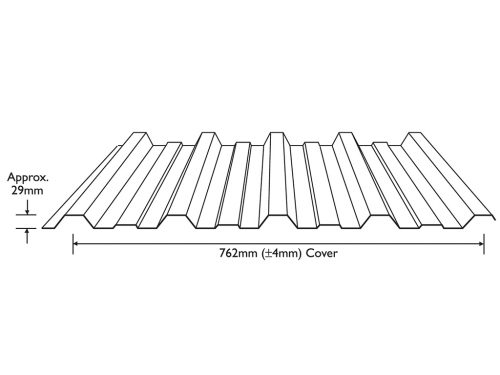

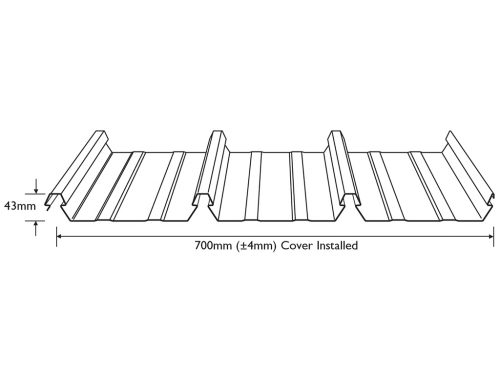

Concealed Fix 700 (Klip-Lok equivalent) 0.42 BMT Colorbond

$17.00 / m Exc. GST -

Capacity Plus 0.42BMT Zincalume

$33.44 Exc. GST m